Exploring Different Finishes and Coating Options for Aluminum Panel Sheets in Facades

When it comes to modern facades, building today opt for new-age building materials like ACPs. Durable, versatile, and aesthetically pleasing, ACPs are preferred for several qualities. With a plethora of finishes and coatings, these materials are ideal for creating a wide range of designs.

Offering visual appeal and environmental protection, aluminium panel sheet offers plenty of options for architects and designers. In this blog, let’s discover the types of coating and finishes that are commonly available.

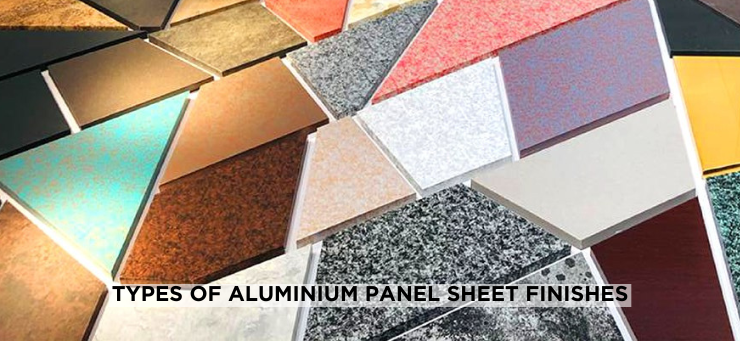

Types of Aluminium Panel Sheet Finishes

Glossy and Matte Finish

ACP panels are available in a wide range of finishes including glossy and matte. These ACP panels are painted in a plethora of colours and sealed with glossy and matte coatings. Catering to the needs of a wide range of building cladding requirements, these ACPs are ideal for both exterior and interior applications. While glossy ACPs make eye-catching designs, matte ACPs offer facade designs without shine.

Wood Grain Finish

Whether it’s adding a natural and warm aesthetic to their facades, or bringing back the vintage decor, wooden finishes on aluminium panel sheets are an excellent choice. Woden ACPs create a realistic wood-like appearance while being immune to low durability and high maintenance.

Brushed Finish

Brushed finishes on aluminium composite panels create a distinctive and elegant look. This finish is achieved by brushing the aluminium surface with a wire brush, creating a pattern of fine lines or strokes. Brushed finishes can be further enhanced by anodizing or clear coating to protect the surface and give it a polished appearance.

Mirror Finish

Aluminium panel sheet with mirror finishes are used to create a striking visual effect in facades. The reflective surface of the panels adds depth and dimension to the building's exterior while reflecting its surroundings.

Types of Aluminium Panel Sheet Coatings

Powder Coating

Powder coating is a popular choice for aluminium panel sheets as it offers a wide range of colours and finishes. It involves applying a dry powder to the surface of the aluminium and then curing it. The result is a durable, uniform, and high-quality finish that is resistant to chipping, cracking, and fading. Powder coating is considered to be up to two times more durable than just paint. Powder coating can is primarily used in curtain wall glazing.

PVDF Coating

Polyvinylidene fluoride or PVDF coating is a liquid-based coating system. This offers a highly durable finish that provides excellent resistance to fading, weathering, and chemical exposure. It is often used in high-traffic areas or in regions with harsh climates. PVDF coatings offer a wide range of colours and are known for their ability to retain colour vibrancy and gloss over time. ACP panels with PVDF coating are known to have self-cleaning properties, making them suitable for facades that require minimal maintenance.

Conclusion

Both the finish and coating for aluminium panel sheets in facades play a crucial role in determining the visual appeal and long-term performance. The best way to make a decision is to go through different finishes and coatings, as well as evaluate the area of application. Besides, it’s best to consult with a professional before you make a decision.

Comments

Post a Comment